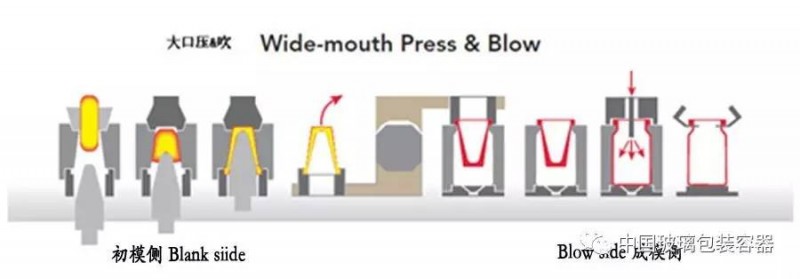

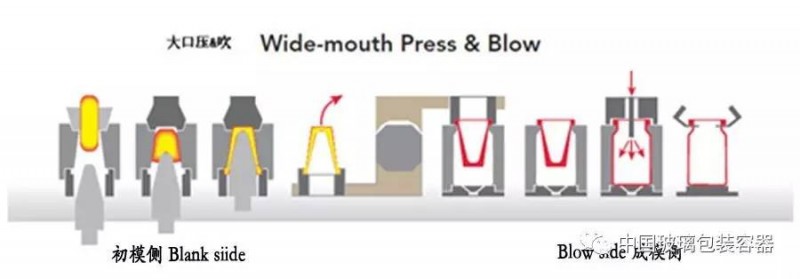

PRESS & BLOW:

An expression used to identify the production processof an I.S. machine where the parison is formed by pressing a plunger intothe glass in the blanks.

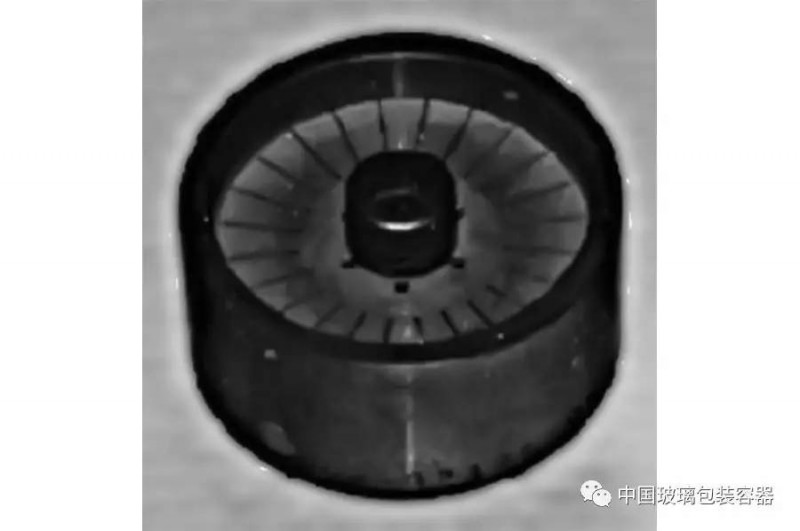

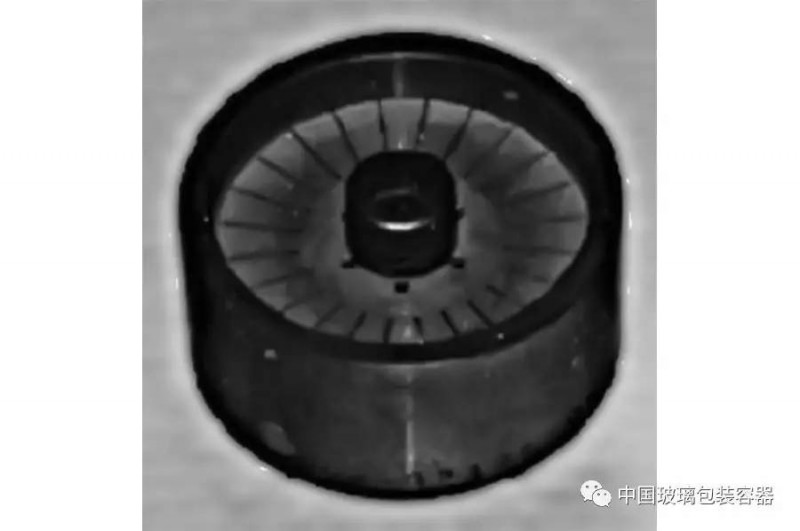

PRESS & BLOW MOLD EQUIPMENT

PRESS & BLOW MOLD EQUIPMENT

1. Funnel

The funnel has one function only. It acts as a guide for the gob to enter the blank.

2. Blank

The blank is the primary piece used to form the parison as the plunger presses the glass. It is designed to provide the correct amount of glass wall thickness throughout the finished container.

3. Baffle

The baffle seals the end of the blank forming the complete blank cavity.

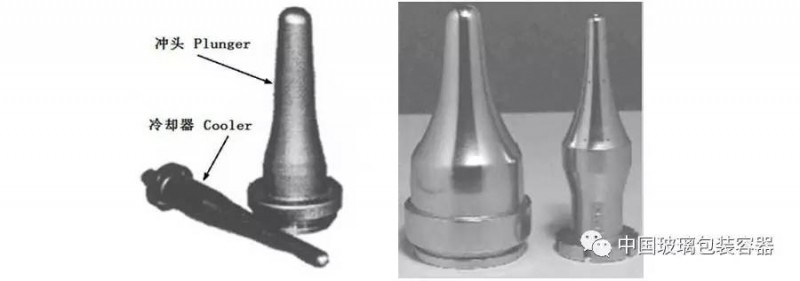

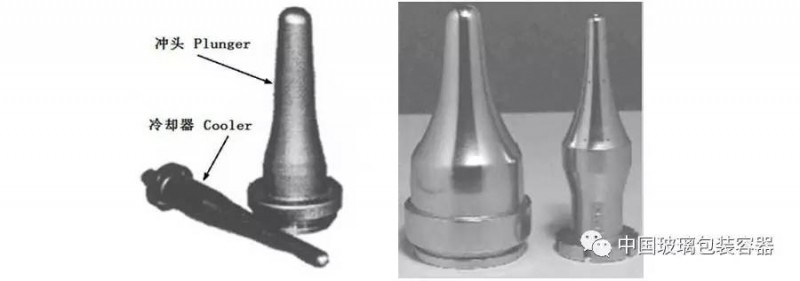

4. Plunger

The plunger travels in an upward motion pressing the glass in the blank and neck ring. This action forms the parison and the finish. The plunger is cooled internally by air flowing through the cooling tube.

5. Neck Ring

The neck ring consists of two neck ring halves and a guide ring. The guide ring is an internal part and normally forms the top of sealing surface of the finish. The neck ring forms the finish and holds the parison during transfer from the blank to the mould. The guide ring is sometimes referred to as guide plate.

6. Mould

The mould forms the finished container.

7. Bottom Plate

The bottom plate is used in conjunction with the mould to form the finished container. The bottom plate forms the bottom of the container.

7. Blow Head

The blow head sits on top of the mould. It is used to introduce final blow air into the parison blowing it to the shape of the mould.